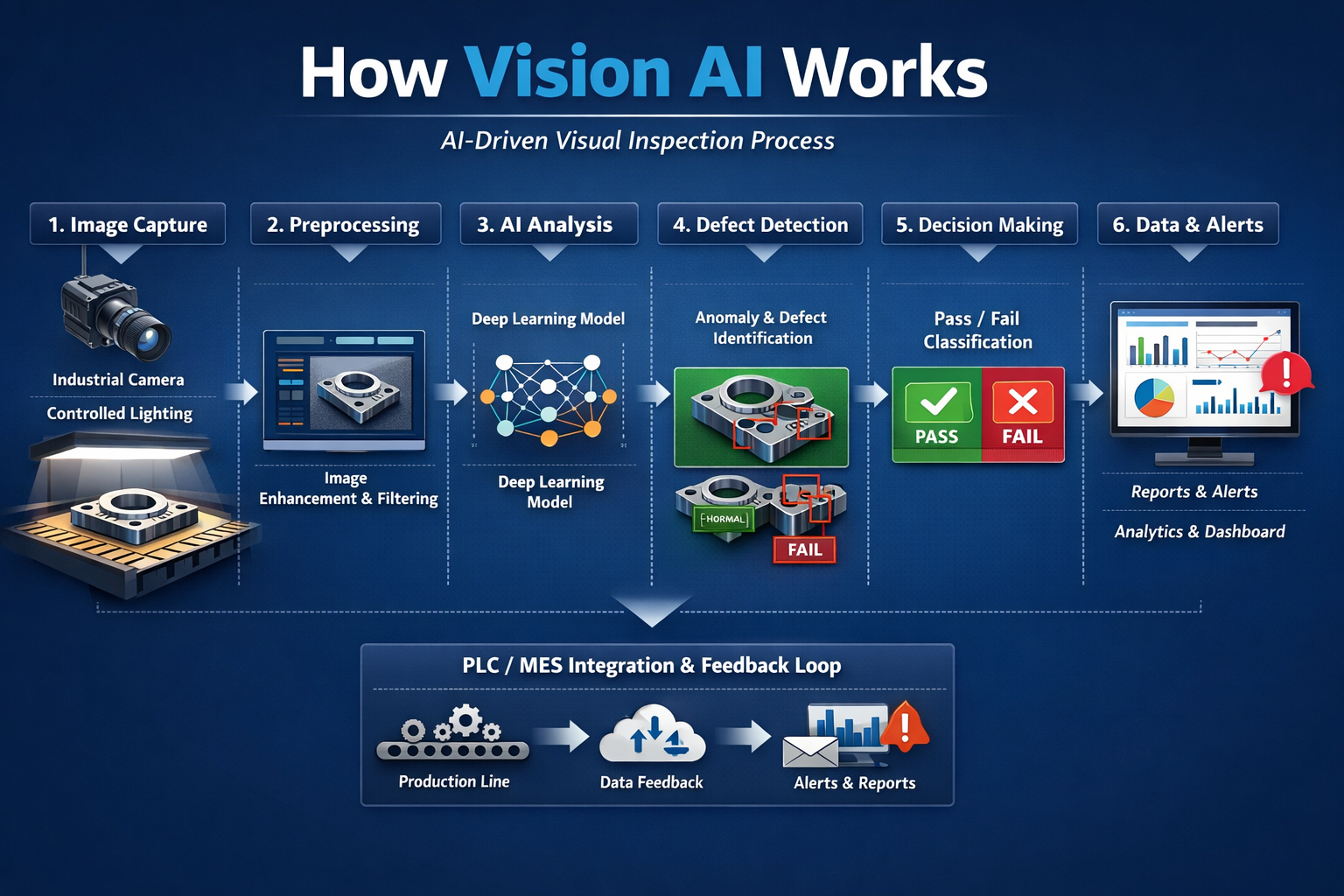

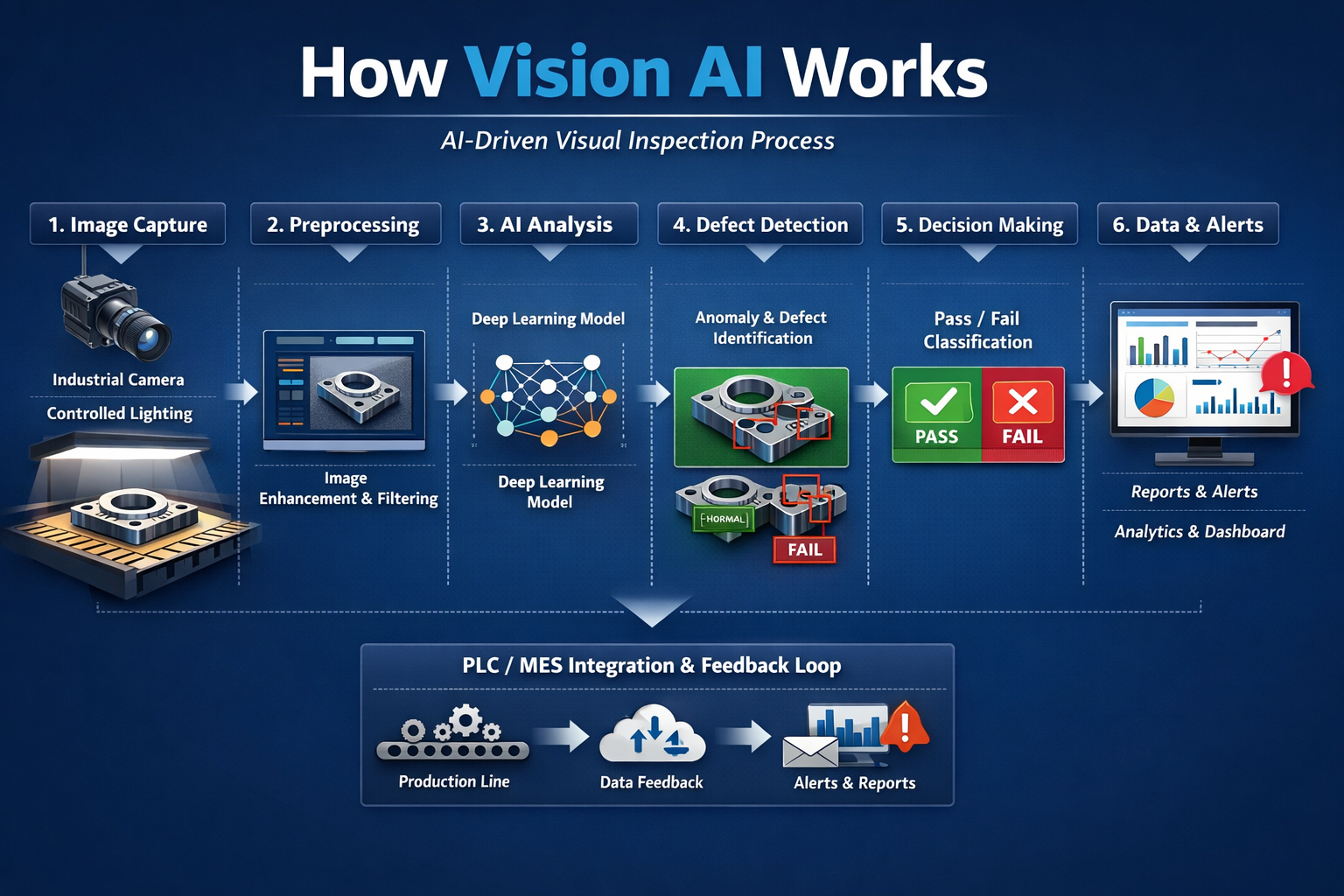

How Vision AI Works

AI-Driven Visual Inspection Process

From image capture and preprocessing through AI analysis and defect detection to pass/fail decisions, reports, and PLC/MES integration.

AI-driven visual inspection for manufacturing: defect detection, quality control, and real-time insights at machine speed.

Vision AI is a branch of Artificial Intelligence that enables machines to see, understand, and act on visual data such as images and videos. By combining cameras, optimized lighting, deep learning models, and industrial software, Vision AI systems can identify defects, measure dimensions, verify assembly, and monitor safety in real time.

Unlike traditional rule-based vision systems, Vision AI learns from data, making it highly adaptable to complex surfaces, variable lighting, and subtle defects that are difficult to define using fixed rules.

AI-Driven Visual Inspection Process

From image capture and preprocessing through AI analysis and defect detection to pass/fail decisions, reports, and PLC/MES integration.

Scratches, dents, cracks, pits, stains, discoloration. Suitable for metals, plastics, glass, rubber, and coated surfaces. Detects micro-defects invisible to the human eye.

Missing or misaligned components, incorrect assembly sequence, tolerance and dimensional verification.

OCR for serial numbers, batch codes, expiry dates. Barcode and QR code validation. Print quality and alignment checks.

PPE compliance (helmets, gloves, vests). Unsafe human-machine interactions. Restricted zone violations.

Detects deviations from normal operation. Identifies rare or unknown defects. Enables predictive quality control.

Ready to build something amazing together?